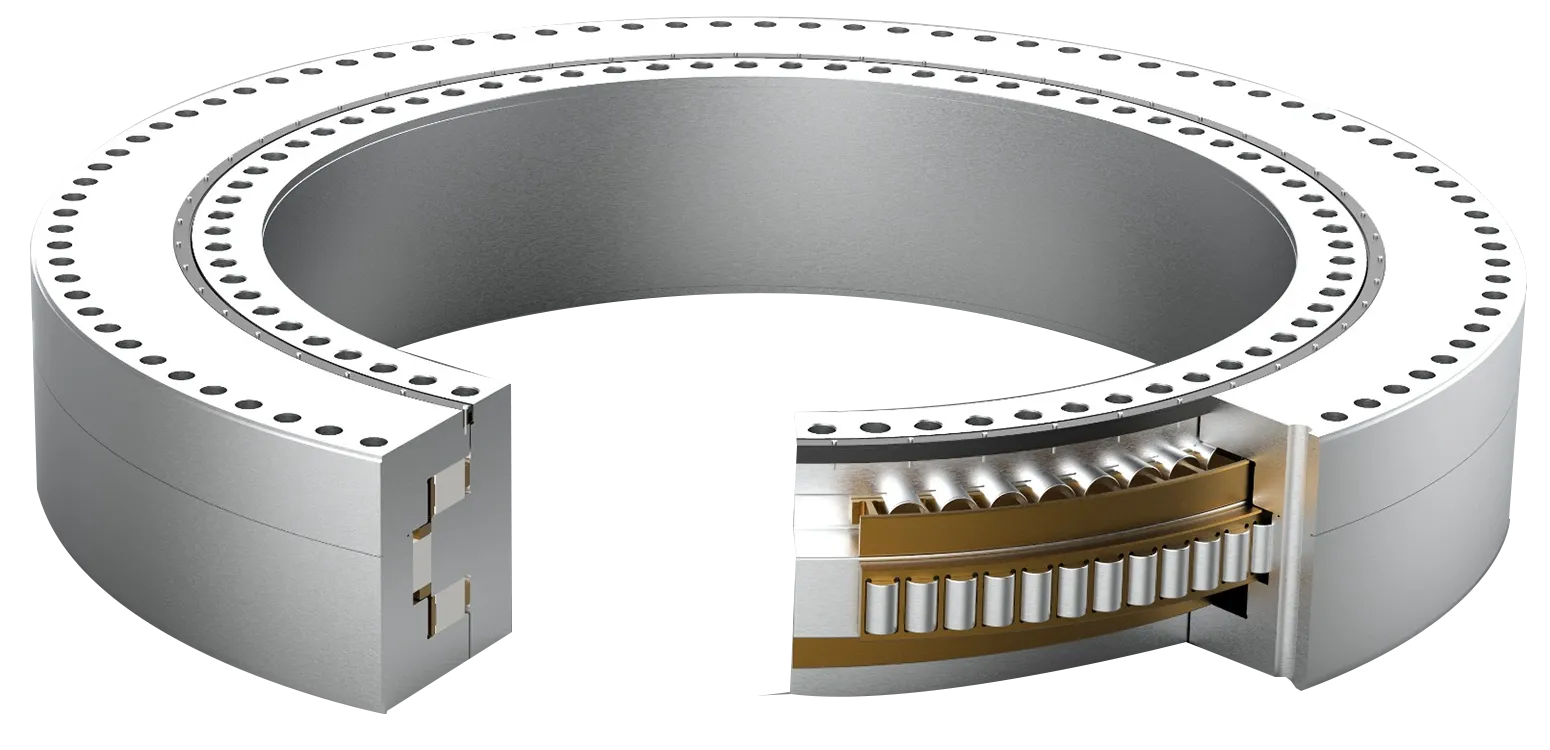

Three-row cylindrical roller bearings are designed with a robust structure that includes two rows of thrust rollers and one row of radial rollers. This arrangement can be configured with either an outer ring assembly and an integrated inner ring or vice versa. The strength of this design makes it particularly suitable for direct-drive wind turbines, where it can withstand the aerodynamic loads generated by the turbine, including axial loads, radial loads, and overturning moments.

Each row of rollers in the bearing is specifically tasked with handling different types of loads, allowing the bearing to efficiently manage large axial, radial, and overturning forces with minimal deformation. The use of an alloy cage in the bearing’s interior enhances its structural integrity, provides excellent wear resistance, and minimizes heat generation, which is crucial for maintaining long-term reliability.

LYXQL achieved the domestic production of these bearings in 2011, successfully replacing imported products. The wind turbines equipped with these bearings have been operating smoothly for nearly 14 years, demonstrating their durability and high performance in demanding conditions.

Specialists in bearings for wind turbines, marine equipment, and tunneling machines. We deliver quality, expertise, and reliable service.