LYXQL offers more than just large slewing bearings; we also supply various bearing components such as forgings, machined parts, steel balls, rollers, and cages. Our comprehensive product portfolio allows customers to procure all necessary bearing components from a single, reliable source, ensuring compatibility and quality across the board.

Our forging capabilities cover a wide range, with diameters ranging from ⌀50mm to ⌀12000mm and an annual production capacity exceeding 300,000 tons. We specialize in producing forgings weighing up to 80 tons per piece, including marine ring forgings, wind turbine tower flanges, furnace flanges, hub forgings, rim forgings, friction disc forgings, yaw ring forgings, and slewing ring forgings for excavators. These high-quality forgings are widely used in industries such as wind energy, aerospace, shipbuilding, and construction machinery, meeting the rigorous demands of these sectors.

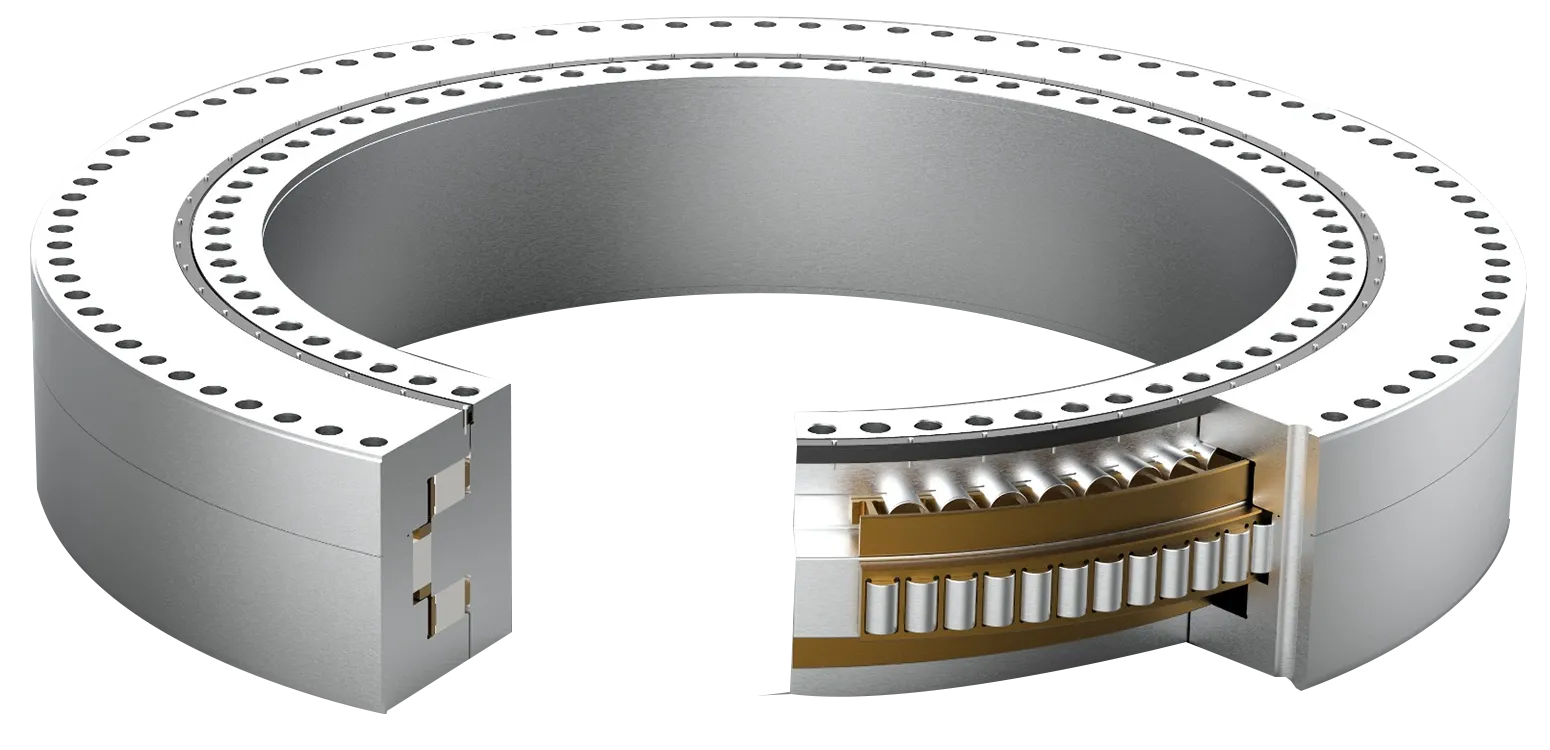

Our machined bearing parts cover a broad range, with sizes ranging from ⌀100mm to ⌀12000mm. These parts primarily include various types of rings, such as toothed rings, full rings, half rings, fan-shaped segments, and other custom shapes, tailored to meet the specific needs of our clients.

We specialize in producing steel balls ranging from ⌀12.7mm to ⌀250mm, designed to meet the precision needs of industries like wind power and construction machinery. These steel and stainless steel balls are available in grades from G10 to G500, ensuring high performance in various applications. With an annual production capacity of 8,000 tons, we are equipped to support large-scale projects with consistent quality.

We offer an extensive range of cylindrical, tapered, and spherical rollers, with diameters ranging from ⌀12mm to ⌀183mm and lengths between 15mm and 250mm. These rollers, available in precision G1 and G2, are integral to various applications such as yaw and pitch bearings, main shafts, gearboxes, slewing bearings, port machinery bearings, and tunnel boring machine bearings. With an annual production capacity of 10,000 tons, we ensure that our rollers meet the stringent demands of high-performance industries like wind power and heavy machinery.

Our large-scale production capabilities allow us to manufacture both large and extra-large forgings, meeting the demands of various industries. We ensure timely and high-quality delivery for all major engineering projects.

Our bearing parts production facilities are equipped with cutting-edge machinery, including 47 different types of saws, 12 large ring rolling machines, 4 free forgings, and 6 heat treatment lines. These investments in technology boost production efficiency and reduce costs.

We maintain stringent quality control throughout the entire production process, from raw material inspection to finished product testing. Our comprehensive quality management system has earned recognition from major ship classification societies for our precision forging technology.

We offer a wide range of materials and shapes to meet various application needs. Additionally, we provide customized production based on specific customer requirements, delivering personalized solutions for unique challenges.

Specialists in bearings for wind turbines, marine equipment, and tunneling machines. We deliver quality, expertise, and reliable service.