Custom solutions that fit your needs

We have strong capabilities in designing and producing wind turbine main bearings, yaw bearings, pitch bearings and gearbox bearings. As one of the leading suppliers of wind turbine bearings, we are backed by robust technical expertise and a dedicated R&D team that focuses on the production of large slewing bearings. We invest heavily in research and development each year to drive continuous innovation and improvement.

Our commitment to research and development has led to impressive results over the years. We hold 134 patents, including 27 for inventions. Many of our innovations are recognized as being at the forefront of the industry. For example, In 2023, our efforts in the development of independent pitch bearings for large-scale wind turbines were recognized with the second prize for scientific and technological advancement by the Henan Province. In addition, our company's research and industrialization project for the three- row cylindrical roller main bearings of high-power wind turbines in 2021 won the second prize of China Machinery Industry Science and Technology Award. These achievements reflect our ongoing commitment to innovation and excellence in the slewing bearing industry.

We have a strong foundation in creating original products, consistently increasing our investment in R&D and bringing in talented researchers. With multiple research centers and technical teams, we're focused on enhancing our R&D capabilities and building an exceptional development team. Our company, along with subsidiaries Shengjiu Forging and Haozhi Machinery, is recognized as a high-tech enterprise. Every year, we allocate significant resources to ensure our teams can drive product innovation and technological progress.

We’ve developed a range of wind turbine bearings from 1.5MW to 18MW, achieving import substitution. This includes pitch and yaw bearings, as well as 2-5MW three-row cylindrical roller main bearings and 3-18MW single-row tapered roller bearings, all now in mass production. Our 12MW offshore typhoon-resistant main bearings have successfully tackled key technical challenges in China’s high-power wind turbine sector and have been installed. We’ve also validated and mass-produced 5-7MW spherical roller bearings. Currently, we’re focusing on developing bearings for wind turbines over 20MW, ensuring we’re ready for the next generation of larger turbines.

On July 3, 2024, we completed the production of China’s first ultra-large split slewing bearing with a diameter of 18 meters, weighing 168 tons, about the height of a six-story building. This big bearing, independently designed and manufactured by us, will be installed on a giant floating crane vessel for offshore wind turbine installation.

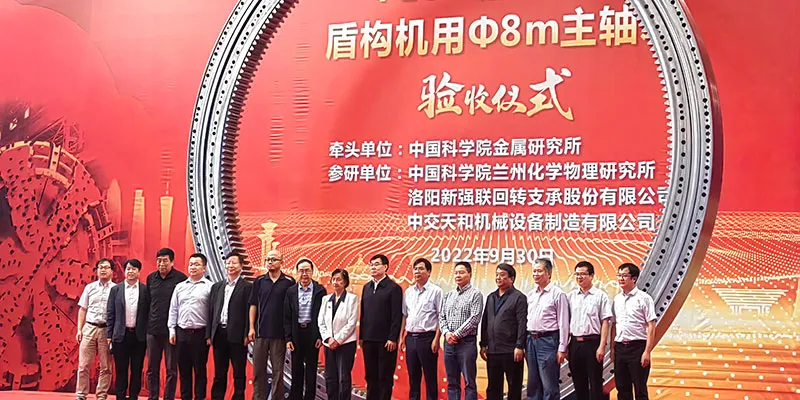

On September 30, 2022, we successfully developed an 8-meter diameter main bearing for use in ultra-large shield tunneling machines. This bearing is the largest and heaviest of its kind ever made in China and will be installed in a domestically developed 16-meter-class ultra-large shield tunneling machine.

On July 28, 2022, we developed a 12MW offshore typhoon-resistant wind turbine main bearing with a diameter of 3.5 meters and weighing over 14 tons. This double-row tapered roller bearing is designed to handle extreme conditions, with the ability to withstand a tilting moment of 47,500 KNM. To meet the demands of harsh offshore environments, we improved the induction hardening process, ensuring the raceway's hardened layer is deep enough for superior load-bearing capacity.

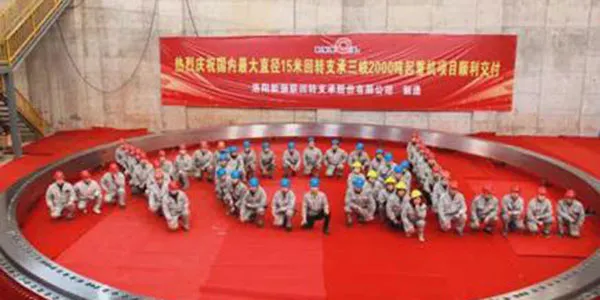

On December 27, 2021, we successfully completed the production of a large slewing bearing with a 15-meter diameter. This custom bearing was created for Shanghai Zhenhua Heavy Industries (ZPMC) and will be used in the crane of a 2,000-ton wind turbine installation vessel. This vessel will be key in installing large offshore wind turbines, overcoming the challenges of offshore wind power installation.

On December 22, 2016, we delivered a large spherical plain bearing forging for the Shantou SuAi Bay Tunnel project. This bearing, designed for a 15-meter diameter shield tunneling machine, set a new record in China by weighing in at 88 tons. It became the heaviest and largest precision rolled ring forging ever produced in the country, marking a significant achievement in our engineering capabilities.

LYXQL is your trusted partner in manufacturing high-quality slewing bearings and custom components. Whether it's wind energy, tunnel boring, or marine applications, we deliver reliable solutions tailored to your specific needs and budget.

Custom solutions that fit your needs