Slewing bearings in large marine equipment, such as crane vessels and floating cranes, are indispensable for managing heavy lifting tasks at sea. LYXQL has established itself as an expert in this field, and continued to lead the market, consistently breaking its own records by producing some of the largest marine slewing bearings in the country.

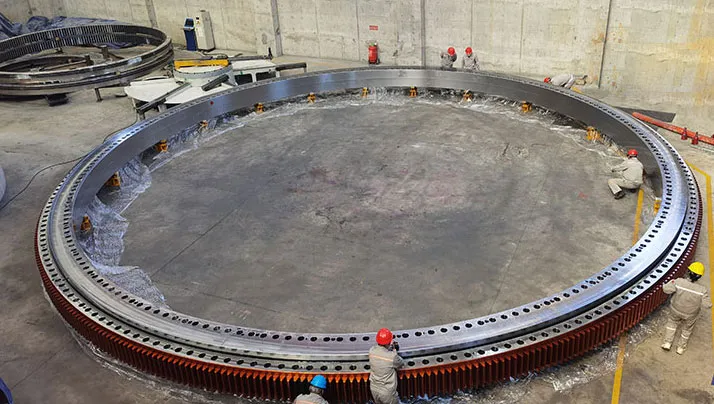

With the increasing scale of offshore wind turbines, there's a growing need for more robust and capable marine equipment. LYXQL has developed advanced slewing bearings for wind turbine installation vessels, with diameters reaching up to 18 meters, as well as for full-rotation floating cranes with diameters up to 11.8 meters. These bearings have offered both economic and operational advantages.

The integrated three-row roller slewing bearings are designed to handle the significant axial, radial, and overturning loads typical in large marine equipment like full-rotation floating cranes and heavy-duty ship cranes. This bearing type is constructed with inner and outer rings, rollers, cages, and seals ...

Split three-row roller slewing bearings are engineered to manage the substantial demands of heavy-duty marine applications. Unlike conventional bearings, these feature segmented inner and outer rings that enable easier transportation and on-site assembly of large-diameter components.

LYXQL is your trusted partner in manufacturing high-quality slewing bearings and custom components. Whether it's wind energy, tunnel boring, or marine applications, we deliver reliable solutions tailored to your specific needs and budget.

We have strong capabilities in designing and producing wind turbine main bearings, yaw bearings, and pitch bearings. As one of the leading suppliers of wind turbine bearings, we are backed by robust technical expertise and a dedicated R&D team that focuses on the production of large slewing bearings.

At LYXQL, we produce large slewing bearings, primarily used in wind power and tunneling industries. Our facility is equipped with advanced machines, including the Saet CNC induction quenching machine, high-speed precision gear milling machines, and CNC five-axis machining centers.

At LYXQL, we take quality seriously. Our production facility is equipped with advanced testing instruments that allow us to inspect everything from raw materials to finished products.