LYXQL (NUPLINK) offers a comprehensive range of bearings specifically designed for both onshore and offshore wind turbines, ensuring that all critical components of the wind energy system are supported. This includes main bearings, pitch bearings, yaw bearings, gearbox bearings, shrink discs, and couplings. These components are important for providing seamless operation across different types of wind turbines, such as double-fed, direct-drive, and semi-direct-drive models. With an excellent manufacturing capacity, LYXQL supports up to 800 wind turbine units per month, handling turbines with a maximum power output of 25MW.

Wind turbine bearings include several key types: main bearings, yaw bearings, pitch bearings, gearbox bearings, and generator bearings. Typically, a wind turbine is equipped with one main shaft bearing, one yaw bearing, and three pitch bearings.

These double-row spherical roller bearings are specially designed for wind turbine main shafts.

Single-row tapered roller bearings are designed to handle both radial and axial loads efficiently, particularly in applications like wind turbine main shafts.

Three-row cylindrical roller bearings are designed with a robust structure that includes two rows of thrust rollers and one row of radial rollers.

Pitch bearings, also known as blade bearings, are important components in modern wind turbines.

Double-row four-point contact ball bearings are designed to meet the demands of wind turbine pitch systems.

Installed within the yaw system at the base of a wind turbine, these bearings are responsible for supporting the entire weight of the main drive system.

As a key component of wind turbines, the gearbox plays a critical role in converting the rotational energy of the blades into electrical power.

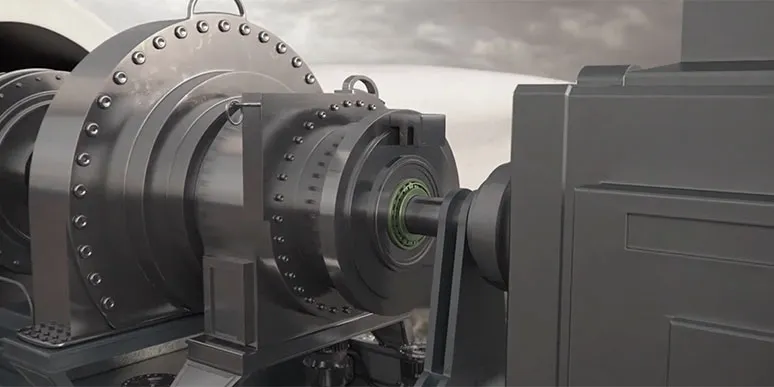

Wind turbine shrink discs ensure the secure connection between the main rotor shaft and the high-speed gearbox shaft, facilitating the safe and efficient transmission of torque within wind turbines.

Wind turbine high-speed shaft couplings are designed to connect the gearbox to the generator in wind turbines.

These bearings are engineered to meet the rigorous demands of wind turbine operations, ensuring that they can withstand the varying loads and environmental conditions typical of both onshore and offshore installations.

LYXQL is your trusted partner in manufacturing high-quality slewing bearings and custom components. Whether it's wind energy, tunnel boring, or marine applications, we deliver reliable solutions tailored to your specific needs and budget.

We have strong capabilities in designing and producing wind turbine main bearings, yaw bearings, and pitch bearings. As one of the leading suppliers of wind turbine bearings, we are backed by robust technical expertise and a dedicated R&D team that focuses on the production of large slewing bearings.

At LYXQL, we produce large slewing bearings, primarily used in wind power and tunneling industries. Our facility is equipped with advanced machines, including the Saet CNC induction quenching machine, high-speed precision gear milling machines, and CNC five-axis machining centers.

At LYXQL, we take quality seriously. Our production facility is equipped with advanced testing instruments that allow us to inspect everything from raw materials to finished products.