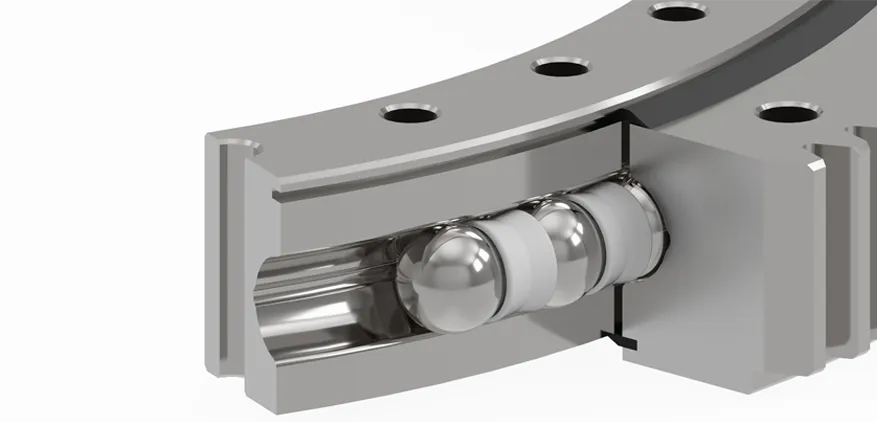

As the demand for wind energy grows, the installation of offshore wind turbines has surged, leading to an increased need for floating cranes. These specialized vessels are equipped with slewing bearings that are crucial for lifting operations, allowing cranes to hoist and position heavy structures during turbine installation. Given the significant lifting capacities often exceeding a thousand tons, the design of these slewing bearings must accommodate high demands, with diameters typically over 10 meters. To address transportation challenges, many slewing bearings are manufactured in segments, enabling easier processing and assembly on-site. This segmented structure requires meticulous design, stringent quality control, and often necessitates certification from maritime authorities to ensure safety and reliability during offshore operations.