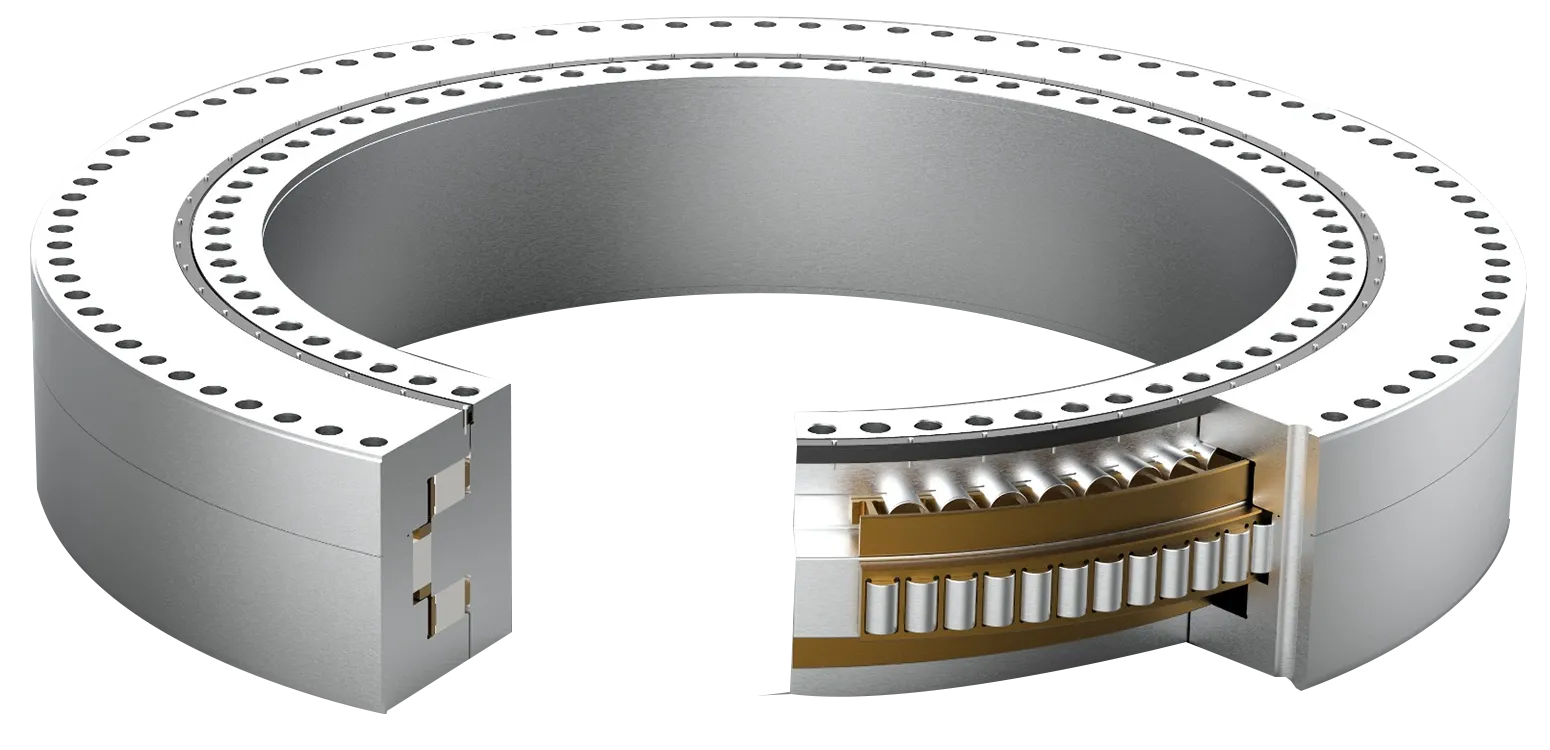

Three-row cylindrical roller slewing bearings is built for applications requiring exceptional load-handling capabilities. With three rows of rollers, this bearing design ensures that the load is distributed across different rows, each dedicated to managing specific force such as axial loads, radial loads, and overturning moments. This configuration provides superior rigidity and stability during rotation, making it highly effective for heavy-duty and complex load scenarios. However, due to its design, it requires precise installation and is more sensitive to any deformations in the mounting structure.

These bearings are typically manufactured using 42CrMo4 steel with induction-hardened raceways to maximize durability. However, depending on the application and customer needs, other materials can be selected to suit specific operational environments.

LYXQL has advanced capabilities in producing Three-row cylindrical roller slewing bearings, tailored to meet demanding industrial requirements. We can manufacture integrated structure bearings with a maximum outer diameter of 12 meters, while for split structures, the maximum outer diameter reaches up to 20 meters.

The gear module size can go up to 45mm, accommodating a wide range of design needs.

(We offer customization options to create non-standard products based on specific user requirements)

Our three-row cylindrical roller slewing bearings are designed to be versatile, available in three distinct configurations: external gear, internal gear, and gearless designs. Each option is built with a robust structure that includes inner and outer rings, rollers, spacers (bearing cages), and seals. To further enhance durability, especially in challenging environments, we offer additional dust-proofing features like dust covers or ash shields based on specific application requirements.

This design features gear teeth on the outer ring. Due to the external location of the gear mesh, this configuration generally requires more installation space compared to internal gear designs. It is ideal for applications where external gear interaction is necessary and where space constraints are not a primary concern.

On July 3, 2024, we completed the production of China’s first ultra-large split slewing bearing with a diameter of 18 meters, weighing 168 tons, about the height of a six-story building. This big bearing, independently designed and manufactured by us, will be installed on a giant floating crane vessel for offshore wind turbine installation.

Our products are widely utilized in wind turbines, marine equipment, tunnel boring machines, and construction machinery. Notably, our wind turbine products are well-known in the market, where we are recognized for offering turnkey solutions that cater to the unique needs of our clients.

Slewing bearing used in offshore crane

Slewing bearing used in offshore crane

Slewing bearing used in floating crane

Slewing bearing used in floating crane

Slewing bearing used in ladle rotary table

Slewing bearing used in ladle rotary table

Slewing bearing used in crawler excavator

Slewing bearing used in crawler excavator

Specialists in bearings for wind turbines, marine equipment, and tunneling machines. We deliver quality, expertise, and reliable service.