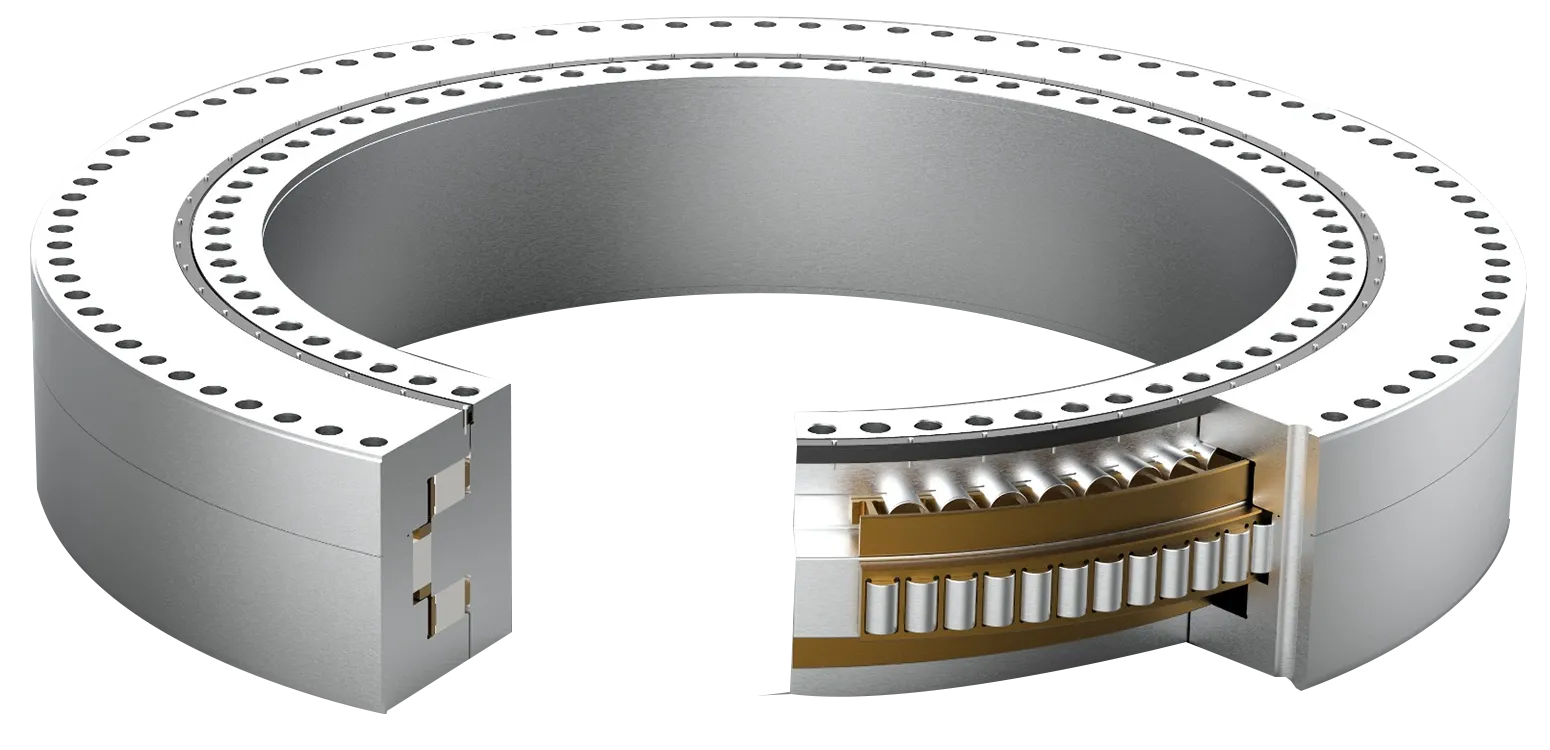

The roller/ball combined slewing bearing integrates both rollers and balls within its structure, providing a balanced approach to load management. The rollers engage in line contact with the raceways, delivering high rigidity and stability, while the balls make point contact, enhancing smooth rotation. This combination allows the bearing to effectively manage various loads, including axial forces, radial forces, and overturning moments, making it suitable for demanding applications.

The dual-row design ensures that each row is optimized for handling specific types of loads, with the rollers supporting heavy axial loads and the balls contributing to rotational accuracy and overall stability. Most of these bearings are designed with an external gear configuration, which generally requires more installation space compared to an internal gear setup but allows for easier maintenance access. If an internal gear or gearless design is preferred, LYXQL can customize the product to meet specific application needs.

Typically, the rings are manufactured from 42CrMo4 steel, with induction-hardened raceways for enhanced durability. Alternative materials can be used depending on the specific requirements provided by the customer.

LYXQL can manufacture roller/ball combined slewing bearings with an outer diameter of up to 20 meters. The gear module size can go up to 45mm.

Our products are widely utilized in wind turbines, marine equipment, tunnel boring machines, and construction machinery. Notably, our wind turbine products are well-known in the market, where we are recognized for offering turnkey solutions that cater to the unique needs of our clients.

Slewing bearing used in excavator

Slewing bearing used in excavator

Slewing bearing used in stacker reclaimer

Slewing bearing used in stacker reclaimer

Specialists in bearings for wind turbines, marine equipment, and tunneling machines. We deliver quality, expertise, and reliable service.