Single-row tapered roller bearings are designed to handle both radial and axial loads efficiently, particularly in applications like wind turbine main shafts. These bearings consist of a conical inner and outer ring, a cage, and a set of tapered rollers. The design allows the inner ring assembly, which includes the rollers and cage, to be installed separately from the outer ring, providing flexibility during installation. Typically used in pairs, the bearing clearance must be adjusted at the time of installation to ensure optimal performance.

The tapered surfaces of the inner and outer rings are engineered so that their projection lines converge at a single point along the bearing axis. This precise alignment enables the rollers to move smoothly, reducing friction and allowing the bearing to manage combined loads effectively. The design is particularly well-suited for wind turbines, where the bearings must accommodate both radial forces and axial loads, ensuring consistent and reliable operation.

LYXQL specializes in producing both single-row and double-row tapered roller bearings, tailored for the demanding conditions of wind turbine main shafts. These bearings are recognized for their ability to manage heavy loads while maintaining long-term reliability, making them a trusted choice for enhancing the efficiency and stability of wind turbines.

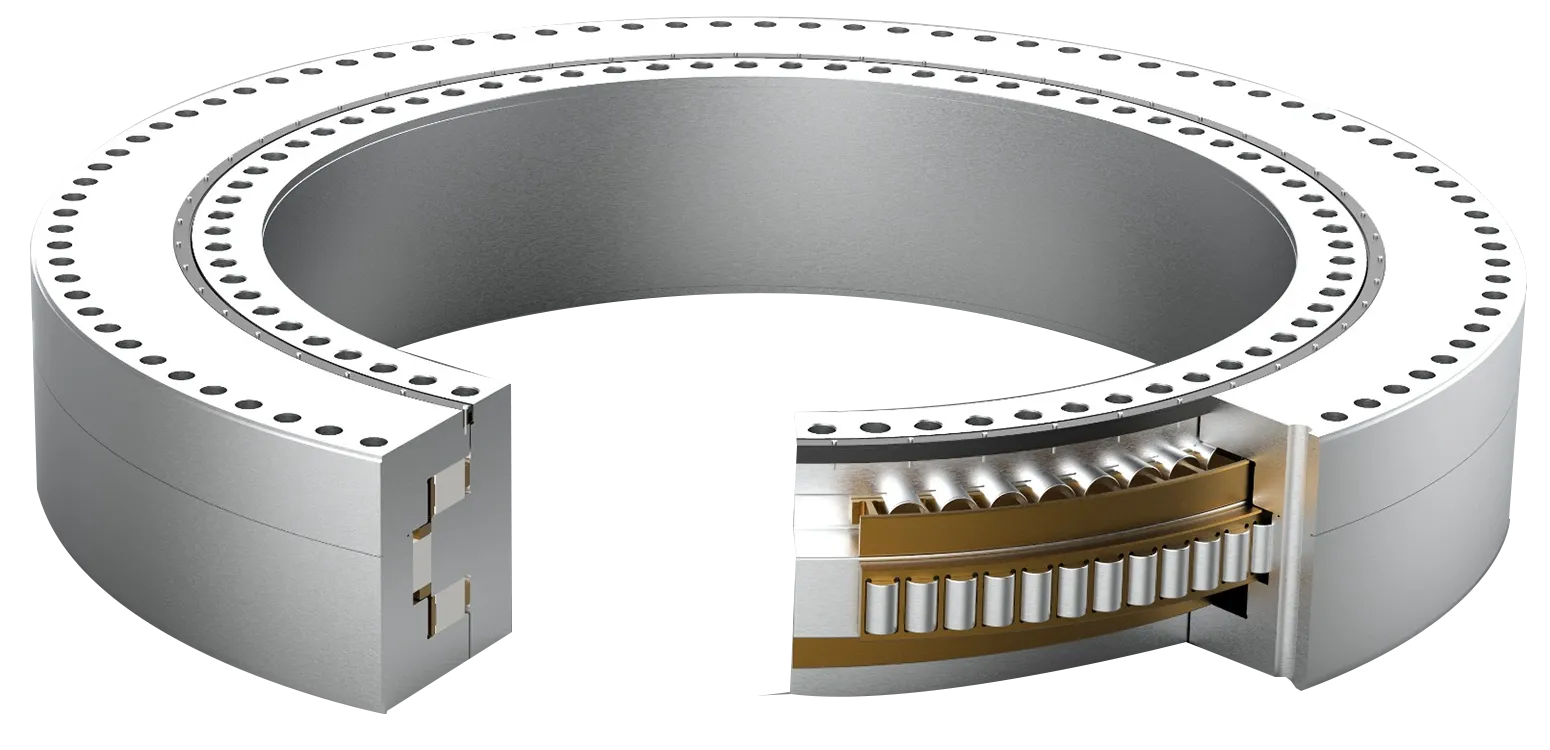

Double-row tapered roller bearings are designed to handle both radial and axial loads efficiently, making them a reliable choice for various applications. These bearings feature a straightforward internal structure with an inner ring, an outer ring, and multiple sets of tapered rollers that are evenly spaced between them.

The rollers in these bearings are conical, allowing them to create a strong contact surface with the raceways. This design enables the bearing to manage significant loads in both the axial and radial directions. The dual-row setup provides extra load capacity and stability, which is especially important in situations where both types of loads are present.

In wind turbine main shafts, these bearings help ensure the system runs smoothly by maintaining a stable operation under different load conditions. Their ability to balance and distribute loads effectively contributes to the overall performance and durability of the equipment.

Both single-row and double-row tapered roller bearings can be customized to meet specific client needs, including different design and manufacturing options. These bearings can be produced using various materials such as carburizing steel, bainitic steel, and alloy steel treated with advanced soft zone-free quenching technology.

LYXQL has supplied these bearings to leading wind turbine manufacturers, including Ming Yang, Envision Group, SANY and DEC. The company has successfully designed and delivered main bearings for turbines ranging from 3MW to 25MW, ensuring they meet the rigorous demands of modern wind energy applications. This customization capability allows LYXQL to cater to the diverse requirements of high-performance wind turbines, enhancing the overall efficiency and reliability of their operations.

On July 28, 2022, we developed a 12MW offshore typhoon-resistant wind turbine main bearing with a diameter of 3.5 meters and weighing over 14 tons. This double-row tapered roller bearing is designed to handle extreme conditions, with the ability to withstand a tilting moment of 47,500 KNM. To meet the demands of harsh offshore environments, we improved the induction hardening process, ensuring the raceway's hardened layer is deep for superior load-bearing capacity.

Specialists in bearings for wind turbines, marine equipment, and tunneling machines. We deliver quality, expertise, and reliable service.