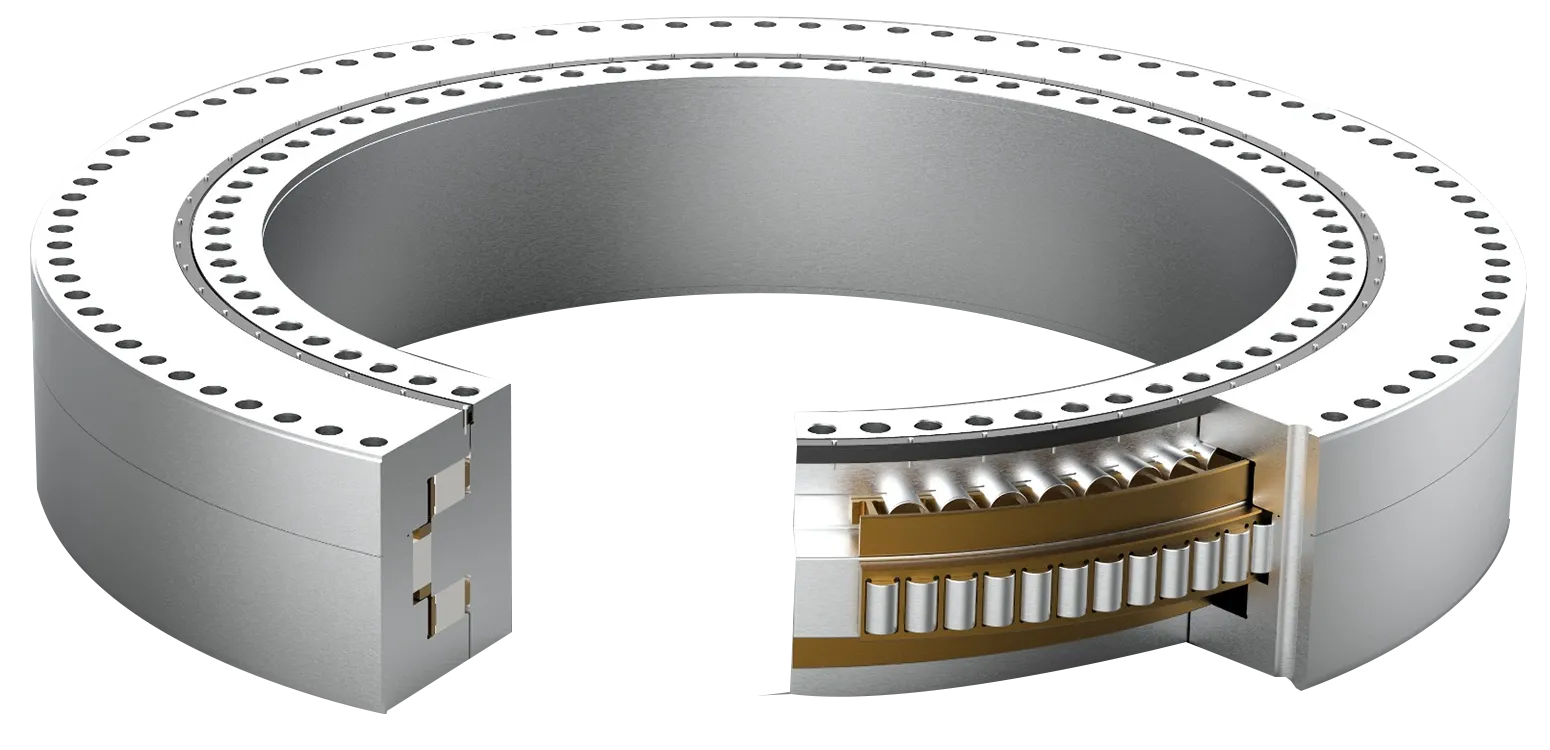

Split three-row roller slewing bearings are engineered to manage the substantial demands of heavy-duty marine applications. Unlike conventional bearings, these feature segmented inner and outer rings that enable easier transportation and on-site assembly of large-diameter components. This design is necessary to ensure that equipment such as full-rotation floating cranes and large marine cranes can handle significant axial loads, radial forces, and overturning moments with maximum stability and efficiency.

Our standard material of choice is 42CrMo4 steel, renowned for its durability and resistance to wear, with induction-hardened raceways to enhance performance under high stress. However, we offer a range of materials and custom options tailored to specific operational requirements, ensuring that each bearing meets the unique challenges of your marine projects.

Our manufacturing capability for split three-row roller slewing bearings is designed to accommodate the production of bearings with a maximum outer diameter of 20 meters, ensuring we can meet even the most demanding size requirements. The gear module reaches up to a maximum of 32mm, allowing for precise customization based on client specifications.

(We also offer tailored solutions for non-standard products to suit specific operational needs.)

Specialists in bearings for wind turbines, marine equipment, and tunneling machines. We deliver quality, expertise, and reliable service.