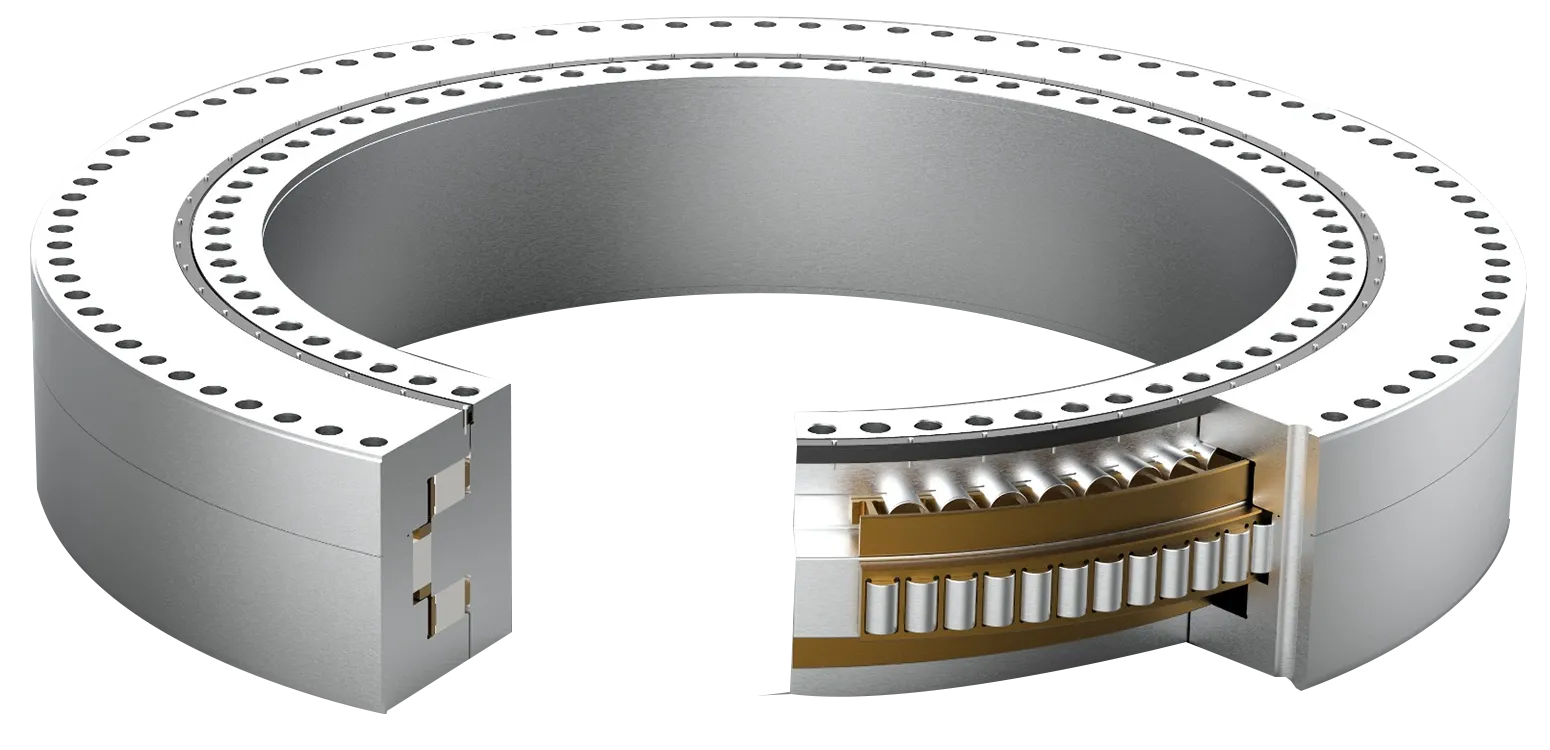

These double-row spherical roller bearings are specially designed for wind turbine main shafts. Their construction includes two rows of rollers, with the outer ring featuring a shared spherical raceway and the inner ring having two raceways angled relative to the bearing axis. This design enables the bearing to self-align, making it less sensitive to seat misalignment or shaft deflections, which are common in wind turbine operations. This self-aligning feature is particularly beneficial in situations where installation errors or shaft bending might occur, ensuring smooth and reliable operation.

Thanks to this self-aligning capability, the bearing can efficiently handle both radial loads and axial loads in either direction, making it highly versatile. It also has a high radial load capacity, which is crucial for managing the heavy loads and vibrations typical in wind turbine operations. The design also reduces the need for high precision in the housing, allowing for easier installation and reducing the risk of issues caused by minor errors or shaft deflections.

LYXQL manufactures these double-row spherical roller bearings for various wind turbine models, and they are widely used by leading companies such as Mingyang, Envision, and SANY. These bearings are chosen for their reliability and durability, ensuring that wind turbines operate smoothly and efficiently.

This combination of self-aligning properties and robust load-handling makes double-row spherical roller bearings a reliable choice for wind turbine main shafts, contributing to the overall efficiency and longevity of the turbines.

Specialists in bearings for wind turbines, marine equipment, and tunneling machines. We deliver quality, expertise, and reliable service.